The complete solution for precision end-face fiber optic cable cleaning.

Contains everything needed to eliminate the #1 cause of fiber optic link failure: contamination

Supports all fiber connector types in datacenter and campus environments

Quick Clean™ Cleaners—no training required!

Solvent pen precisely dispenses specially formulated fiber optic cleaning solution

Cards for convenient cleaning of fiber end-faces

Rugged carrying case stores and transports all fiber optic cleaning tools

Dirt, dust and other contaminants are the enemies of high-speed data transmission over optical fiber. Today's network applications require more bandwidth than ever, making loss budgets tighter than ever. Hence, it is critical that all optical connections are free of contaminants to avoid having application performance issue.

Fluke Networks' Fiber Optic Cleaning Kits contains the best fiber optic cleaning tools to effectively remove the toughest contaminants in any fiber network. You can choose between the easy-to-use Quick Clean Cleaners, the convenient cleaning cube/card and the best optic solvent pen to clean both patch cords and fiber end faces inside ports. All fiber optic cleaning materials are lint-free and enable an optimal wet and dry cleaning process.

What To Avoid When Cleaning End-faces

There are as many different cleaning techniques as there are fiber optic network technicians. While some techniques work some of the time, reliable and lasting performance of your fiber links require inspection and proper cleaning processes with every mating. Here are some well-known bad habits:

Dry Cleaning: Traditionally, dry cleaning has been proven to be only partially effective in eliminating contaminants from fiber end-faces and connectors. The challenge had been that the dry cleaning materials were either not good enough to uplift the various types of dirt or greasy contaminants, or they actually introduced static to the fiber ferrule that attracts dust. With technological advancement and better dry cleaning materials, however, a new class of fiber cleaning tools have been created to provide a cost effective and efficient solution for cleaning more than 50% of contaminants from optical networks. It is therefore very important to avoid using simple swabs or cleaning papers to perform dry cleaning on any fiber connectors. Instead, use Fluke Networks’ Quick Clean Cleaner to eliminate most of the dust and harmful particles in your fiber plant.

Wet Cleaning: Cleaning with only a pre-soaked wet wipe or excessive solvent will leave liquid behind on the end-face which also causes problems. As that excess solvent dries, it can leave behind of film of dissolved contaminants that were never properly removed. In addition, residual isopropyl alcohol (IPA) can leave behind a “halo” as it dries that not only causes attenuation, but also can be very hard to remove. No solvent should remain at the conclusion of a cleaning.

Canned Air and Dusters: Canned air and dusters are ineffective and should not be used to clean end-faces. The only thing dusters do is blow large particles around. On a patch cord, this may be effective, but inside a port this can result in those same particles settling elsewhere. Dusters are ineffective on smaller, statically-charged particles and totally useless on oil-based contaminants such as buffer gel or body oil. Last, dusters often expel a propellant that becomes a whole new contaminant that now requires an effective cleaning process to remove.

Thinking New Equals Clean: Do not be lulled into thinking that end-faces on factory-terminated patch cords or pigtails will be clean when they are brand new and covered with a dust cap. Though dust caps are great at preventing damage to the end-face, the caps themselves can be a source of contamination. The plastic used to create dust caps will outgas a residue as its plasticizers deteriorate over time and the surface of the cap may contain mold-release substances used in their high-speed production process. Don’t be surprised to find a contaminated end-face upon removal of a protective cap. For repeatable and reliable end-face cleaning, always use Fluke Networks’ tools to follow the recommended

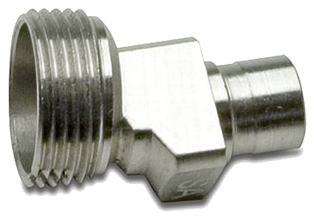

A USB Fiber Inspection Video probe for Versiv products plus tip set (LC, FC/SC bulkhead, 1.25 and 2.5mm universal tips in a box).

FI-7000 FiberInspector™ Pro

2-second automated PASS/FAIL certification of fiber optic connector end-faces

Automated Pass/Fail certification of fiber optic connector end-faces

Graphical indication of problem areas due to contamination, pits, chips, and scratches

Certify to industry standards - IEC 61300-3-35

Eliminate human subjectivity from fiber optic connector end-face measurements

Save fiber optic connector end-face views during certification process

Fiber optic connector end-face contamination is a leading cause of fiber failures. Dirt and contaminant cause insertion loss and back-reflection that inhibits optical transmission and causes havoc with transceivers. Fiber loss and OTDR testing can expose this problem, but in many cases, dirty connections make fiber testing time consuming and inaccurate.

Since dirt can be an issue before, during, or after fiber optic certification testing, and migrate from one fiber optic connector end-face to another upon mating, both sides of any connection must always be cleaned and inspected. Further, mating contaminated fiber optic connectors can cause permanent damage as microscopic debris is crushed between end-faces in physical contact. Even factory terminated patch cords or pigtails must be inspected as protective caps do not keep fiber optic connector end-faces clean. Avoiding this common cause of failure, starts with inspecting the fiber optic connector end-face and eliminating any contamination before insertion into a bulkhead or piece of equipment.

The FI-7000 FiberInspector Pro is a fiber optic inspection scope that allows you to inspect and certify fiber optic connector end-faces in 2 seconds so you can get the job done the first time. This fiber optic inspection scope provides automated PASS/FAIL certification take the guess work out of fiber inspection so anyone can be a fiber expert.

Fiber Inspection Certification

Certify your fiber end-faces to industry standards - IEC 61300-3-35. Or if you prefer, you can manually grade your end-faces.

Graphical indication of Problem Areas

FiberInspector Pro highlights defects found on fiber end-faces. Instead of just coloring the defect area, the FI-7000 colors the defect and highlights the defect’s background so that the defect is clearly visible. Defects that fail the standard’s requirements are colored Red, while defects that pass are colored Green.

Store End-face Images

Store both end-face images of a fiber directly in your Versiv test results. Combine end-face images with CertiFiber Pro OLTS and/or OptiFiber Pro OTDR test results for the complete history of your fiber cabling health.

Built on the Versiv Platform

The FI-7000 is built on the Versiv Cable Certification Platform which enables you to easily add optical loss (OLTS) and Optical Time Domain Reflectometry (OTDR) or even twisted pair copper or network analysis functionality to FI-7000. Product add-on kits are available for the DTX CableAnalyzer, CertiFiber Pro OLTS, OptiFiber Pro OTDR and OneTouch AT Network Assistant.

Versiv’s ProjX™ System

Versiv’s ProjX™ System manages jobs from setup to systems acceptance, ensuring that all tests are completed correctly. Enter the testing details for a job once, and ProjX stores them in a project file with a name the whole team can understand. Change modules or jobs without having to re-enter details. Support multiple testers on the same job by sharing project files via USB sticks or email. Easy just met efficient.

Set-up or view test limits, and testing attributes.

Project menu screen shows percent complete

per job.

Project Specific screen shows up to the minute project details.

Taptive™ User Interface

Now you can test across multiple media types and requirements as easy as using a smartphone. Simply, select the job you’re working on, and the large display confirms the test that needs to be performed. Taptive helps you tap into the overall cabling infrastructure faster and more easily.

Taptive user interface simplifies set-up, eliminates errors and speeds troubleshooting.

LinkWare™ Management Software

Project managers have full capabilities to monitor workflow and consolidate test results.

LinkWare pulls data togther into a single report that is easy for customers to understand, showcasing quality and workmanship. LinkWare stats, provides automated statistical reports that turns test results into charts to reveal performance. The report even summarizes your entire cabling and fiber infrastructure in one compact, graphical format, so it is easy to verify margins and anomalies.

Integrate tests from different testers

into one unified report.

LinkWare Stats summarizes all project data

PASS/FAIL Fiber End-face Grading

The FI-7000’s PASS/FAIL fiber end-face grading is available to all Versiv owners. It is included in Versiv firmware v3.0 and higher. To enjoy this free fiber end-face grading, just download the latest Versiv firmware and create a new Project using FiberInspector as the test.

- Review: The 10 Best Wireless Access Points

- Review: The Top 10 Best Ethernet Cables

- What Is An Ethernet Cable And What Does It Do?

- 10 Best CCTV Security IP Cameras For Home & Business

- Review: Best Powerline Adapters In The UK

- Celebrating 20 Years Of Comms Express!

- The Top 10 DrayTek Wireless Access Points

- Best Selling APC Products At Comms Express

- Review: Top 5 Best Performing APC Uninterruptible Power Supply Units (UPS)

- Review: Top 10 Best PDU’s