RJ45 connectors are the little square plugs and their associated sockets that are used in network cabling. Most offices will use these for both phone and data connections to avoid complicating things by having to have two different types of connection.

Connecting new devices to the network requires a patch lead. These can be bought off the shelf, in ready-made form. They come in various lengths and simplify the job of connecting various devices. However, it’s inevitable that from time to time you will need a lead of an odd length or to make a one-off connection somewhere. In these circumstances, knowing how to assemble your own RJ45 connections makes life easier and saves you having to call in an installer or order a special cable. This means that it can save you money too.

What You Need

In order to make your own network cables, you will need some cable and some connectors, all of which is easily acquired. You will also need a crimping tool and ideally a tester so that you can make sure you’ve done the job properly. Most crimp tools also allow you to strip insulation and cut cables to length.

If you are installing your own sockets, you’ll also need a punch down or ‘Krone’ tool. You can buy all of the tools you need to make up RJ45 connectors as a kit which makes life a little easier.

Making An RJ45 Connector

Okay, so you’ve got all of the bits you need; time to make an RJ45 connector in just seven simple steps.

- Strip Off External Insulation

First of all you need to strip off between three and five centimetres of the external insulation. You may be able to use your crimp tool to do this. Otherwise, use a craft knife and run the blade gently around the circumference of the cable, being careful not to cut any of the insulation on the inner cables. Lightly scoring and then repeatedly bending to cause the outer insulation to shear is usually safer than a deeper cut. When you can see the inner cables all the way around the cut, you can pull the outer insulation off.

- Straighten The Pairs Of Cables

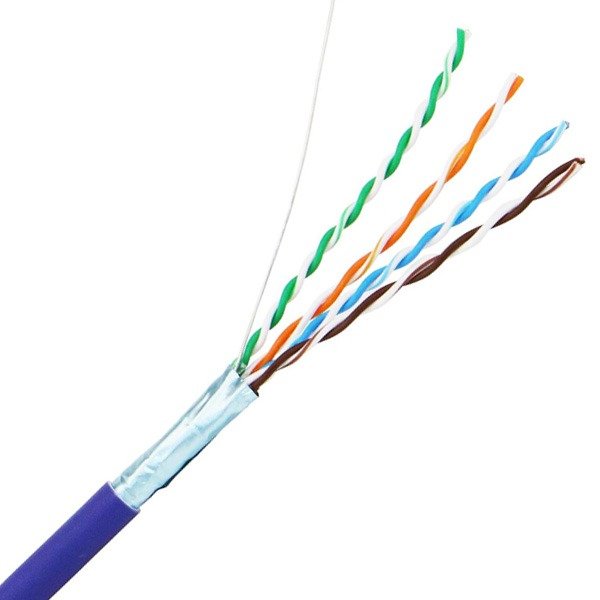

With the outer sheath off, inside you will find four pairs of twisted cables and a central core. The pairs are colour coded as follows:

- Orange and orange/white

- Green and green/white

- Blue and blue/white

- Brown and brown/white

Fold out each of the pairs gently to expose the core. Cut off the exposed bit of the core and throw it away. Now gently untwist each of the exposed pairs and straighten out the wires – pulling them gently through a pair of pliers can help with this.

- Arrange The Wires In Sequence From Right To Left As Follows:

- Orange/white

- Orange

- Green/white

- Blue

- Blue/white

- Green

- Brown/white

- Brown

- Trim The Wires To Length

You may find at this point that your wires vary slightly in length. Hold your RJ45 connector against the edge of the outer insulation and trim off the wires so that they are level with the top of the connector.

- Push The Wires Into The Connector

Now you can push the wires into the connector, making sure that they stay in the correct colour sequence and that each goes into its own channel. You may find it easier to hold the connector gently in the jaws of the crimp tool as you do this. Note that there’s no need to strip the insulation from these wires, the connector is designed so that its pins bite through the insulation when crimped. Make sure that the wires go right to the top of the connector.

- Squeeze The Connector To Lock

Now place your connector into the crimp tool and squeeze it to lock everything together. You can now repeat the process at the other end of the cable.

- Test Your Connection

Finally, use your cable tester to check that you have a good connection. If there’s an error, try re-crimping the connector.

Crimping RJ45 connectors isn’t difficult but you may need a little practice in order to get the hang of it. Don’t worry if your first attempts fail, try again until you get it right.